YASA

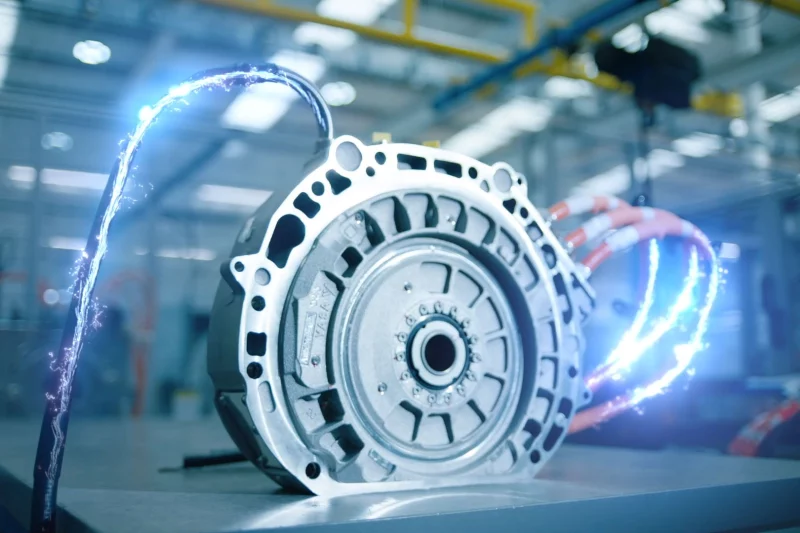

Axial flux motors have recently been gaining significant attention in the electric mobility sector. Contributing to the growing excitement, British innovation leader YASA has revealed plans to launch a cutting-edge “super factory” aimed at increasing production to over 25,000 axial flux electric machines annually. These compact, high-performance pancake motors are primed to drive a variety of top-tier vehicles, including those from Lamborghini and Ferrari.

YASA’s Evolution

Since its spin-off from Oxford University in 2009, YASA has dedicated the past 15 years to overcoming the performance limitations and manufacturing challenges that have hindered axial flux motor technology—issues that date back to the early investigations by pioneers like Michael Faraday and Nikola Tesla in the 19th century.

After initial concepts and prototypes, YASA motors debuted in production cars with the Koenigsegg Regera hybrid. In 2019, Ferrari began producing motors for the Stradale SF90 hybrid. Additionally, YASA has worked closely with Mercedes-Benz, which acquired the company in 2021.

YASA

This month, YASA announced the opening of its upgraded manufacturing facility in Yarnton, near Oxford, UK. The 60,000-square-foot plant represents a £12 million ($16 million) investment to boost production and advance electric motor technology. YASA’s goal is to ramp up annual production to more than 25,000 units.

Redefining Axial-Flux Motor Manufacturing with Innovation and Efficiency

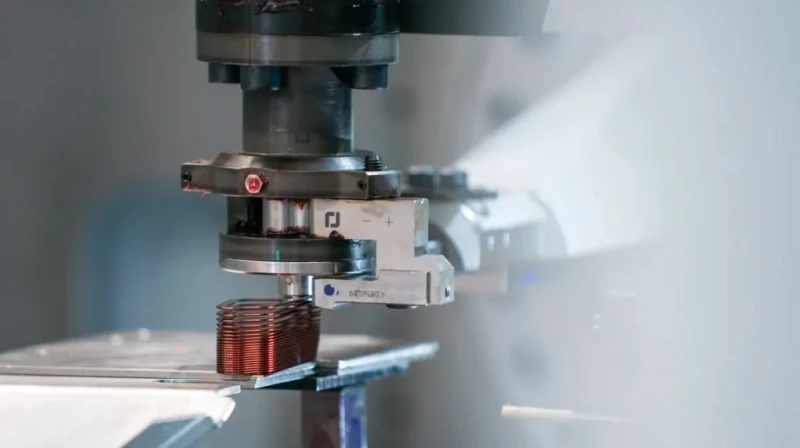

YASA calls the upgraded plant the world’s most advanced for axial-flux motors, and with its innovation leadership, we agree. The facility combines all production processes, streamlining manufacturing with improved automation and efficiency for quality-driven production.

The upgraded facility features advanced machinery, including CNC coil winding, high-capacity ovens, stator laser welding, and rotor balancing for six times greater accuracy.

YASA

Andy North, YASA’s commercial director, stated, “Every technical manufacturing improvement we’ve introduced during the factory upgrade strengthens YASA’s capacity to surpass and outperform all current radial flux technologies by providing more compact, lightweight electric propulsion systems.”

YASA’s axial flux motors produce up to four times the torque and twice the power density of radial flux motors, while being 50% lighter and 80% thinner. One motor in production under Mercedes’ ownership delivers 480 hp (353 kW) and 800 Nm (590 lb-ft) of torque from a 24-kg (53-lb) unit, with a power density of 14.7 kW/kg.

YASA

Powering Lamborghini’s Future

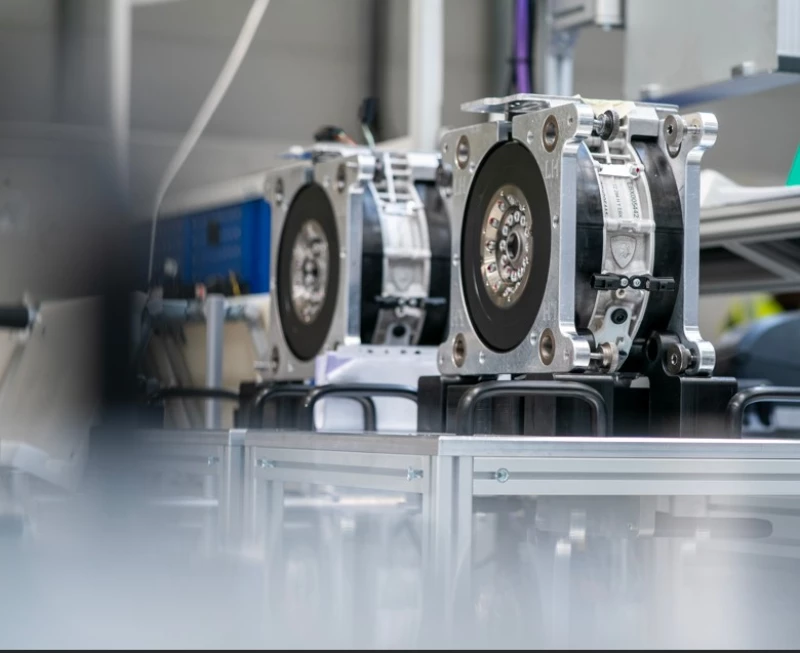

Recently, YASA has supported Lamborghini’s electrification efforts by providing the e-motors for its new High Performance Electrified Vehicle (HPEV) lineup. Lamborghini’s two latest models, part of this family, are powered by YASA’s compact and high-performance e-machines.

The Temerario combines three 148-hp (110-kW) YASA motors and a twin-turbo V8 engine for a total of 907 hp. Each YASA motor weighs 17.3 kg (38 lb) and delivers up to 300 Nm (221 lb-ft) of torque. The Revuelto pairs the same trio of motors with Lamborghini’s new V12 engine, delivering a total of 1,001 hp.

Read the original article on: New Atlas

Read more: Integrated Engine-Motor Drive Retrofits Pure EVs Into Hybrids