A New Type of Plastic Breaks Down in the Ocean More Quickly than Paper

WHOI

Researchers have spent recent years investigating which type of plastic biodegrades most rapidly in marine environments, as millions of tons of plastic enter our oceans each year. They discovered that a common bioplastic, which has been in use for over a century, biodegrades quickly, and they have figured out ways to speed up this process.

Cellulose diacetate (CDA) is derived from cellulose, a natural polymer found in plant cell walls, especially in cotton and wood pulp. This bioplastic has been around since the late 1800s and is used in a variety of products, from sunglasses frames and cigarette filters (its most common application) to photography film and many other items in our daily lives.

Fastest-Degrading Bioplastic Found in Seawater

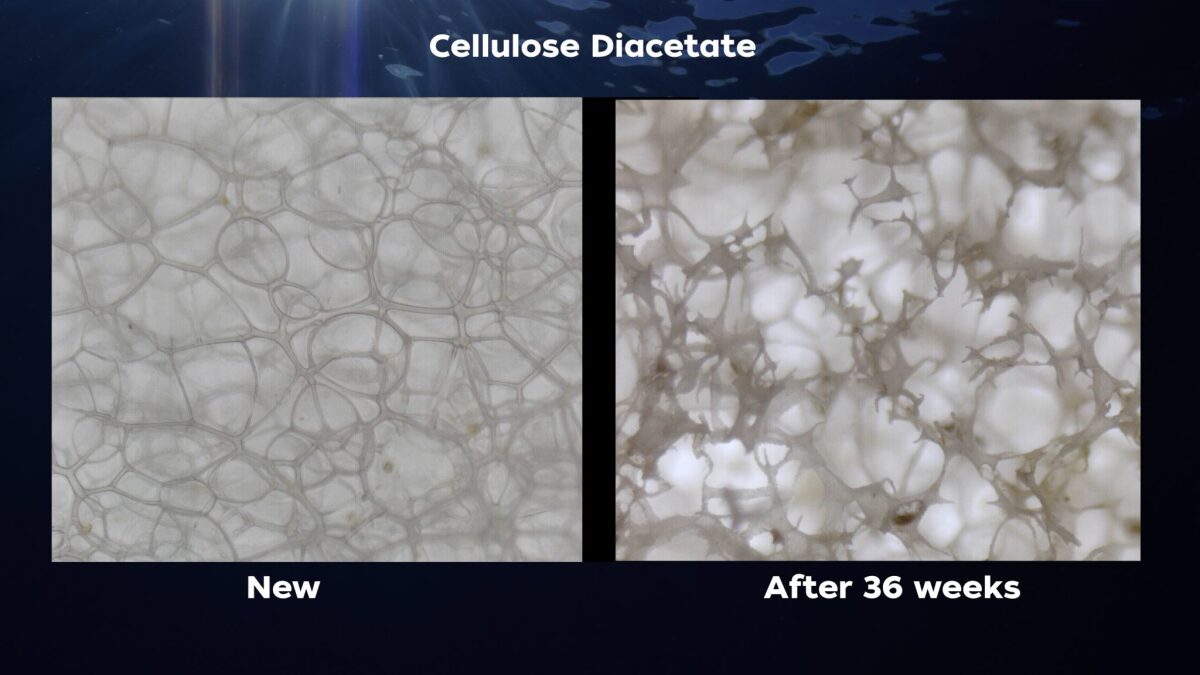

Researchers at the Woods Hole Oceanographic Institution (WHOI) have found that CDA is the fastest-degrading type of plastic in seawater, technically classified as a bioplastic. With a simple modification known as “foaming,” which makes the bioplastic porous, CDA degrades 15 times faster than solid CDA and even more quickly than paper.

“We applied foundational knowledge to create a new material that meets consumer needs while degrading in the ocean faster than any other plastic we know of, including paper,” said Collin Ward, a senior author of the study. “This represents a significant success in a field that often emphasizes the negative aspects of plastic pollution rather than pursuing solutions.”

WHOI

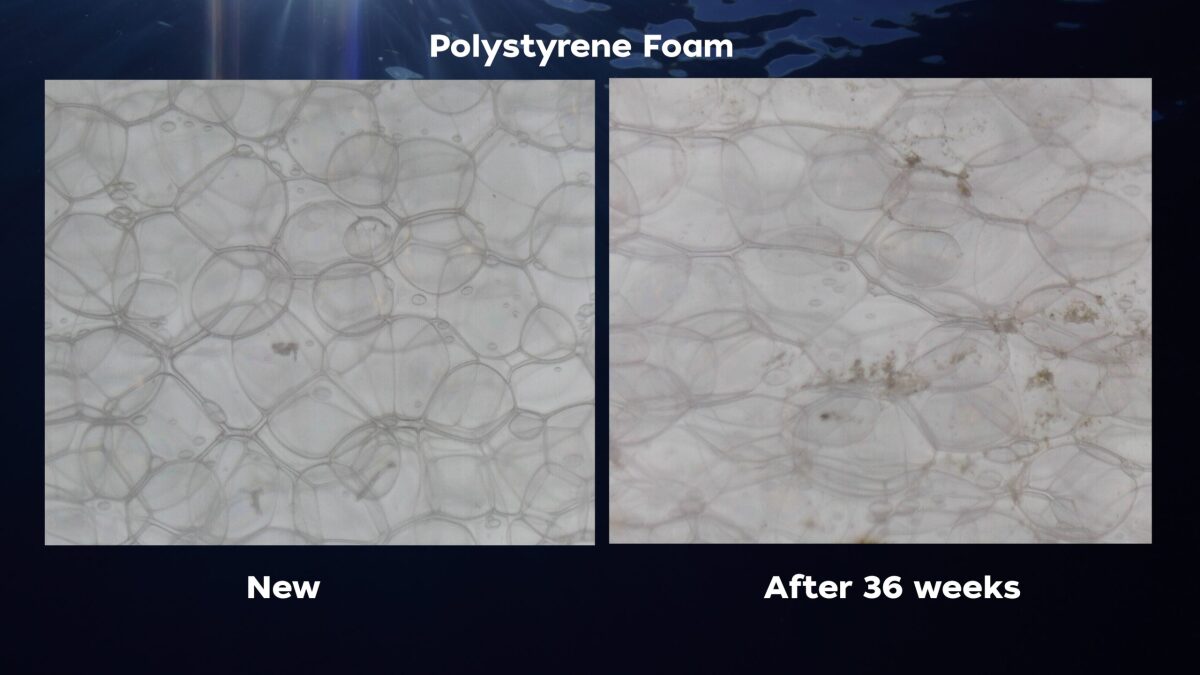

In a 36-week test, CDA foam submerged in continuously flowing seawater tanks lost 65-70% of its original mass. In contrast, Styrofoam, a common plastic found in every ocean worldwide, demonstrated no degradation during the same time frame.

WHOI

Ward and other WHOI scientists collaborated with Eastman, a bioplastic manufacturing company that provided materials, funding, and co-authorship for this and previous studies.

Controlled Laboratory Environment for Marine Research

The research was conducted in a controlled laboratory environment using continuously flowing seawater sourced from Martha’s Vineyard Sound near Cape Cod, Massachusetts. This setup allowed researchers to regulate light, temperature, and other variables to simulate dynamic ocean conditions.

In January of this year, the results of a previous 16-week WHOI study were published. That study utilized the same seawater tank to compare eight different types of straws made from CDA, polyhydroxyalkanoates (PHA), polylactic acid (PLA), polypropylene (PP), and paper.

WHOI

The PLA and PP straws showed no measurable signs of degradation, while the other straws degraded by up to 50%.

Foam CDA Straw Outperforms Solid and Paper Straws

In comparing the prototype foam CDA straw to the solid CDA straw, researchers found that the foam CDA straw degraded 190% faster than the solid version, even outpacing the paper straw (which, fortunately, is a good thing since paper straws have a terrible taste). This led to the recent focused study by WHOI on foam CDA.

Building on the success of foamed CDA, Eastman has introduced a biodegradable and compostable tray designed to replace conventional Styrofoam trays used for meat packaging, which do not biodegrade in any natural environmental conditions, whether on land or in the sea.

Eastman

Read the original article on: New Atlas

Read more: Alarming Microplastics Found in Human Brains