Engineers have developed a solution to eliminate “dead zones” in the fluid flow of electrodes used for battery-based seawater desalination. By incorporating a physics-driven tapered flow channel design within the electrodes, this breakthrough enables more efficient fluid movement, potentially consuming less energy than conventional reverse osmosis methods.

Desalination technology has long faced challenges to widespread adoption. Reverse osmosis, the most common method, is energy-intensive and costly, as it forces water through a membrane to filter out salt. In contrast, the battery desalination technique uses electricity to remove charged salt ions, but previously required energy to push water through electrodes with irregular pores, limiting its efficiency—until now.

A New Approach: Structured Flow Channels

“Traditional electrodes require energy to pump fluids through because they lack structured flow channels,” explained Kyle Smith, a professor of mechanical science and engineering at the University of Illinois Urbana-Champaign, who led the study. “By creating structured channels, this technique reduces the energy needed and could eventually outperform reverse osmosis in efficiency.”

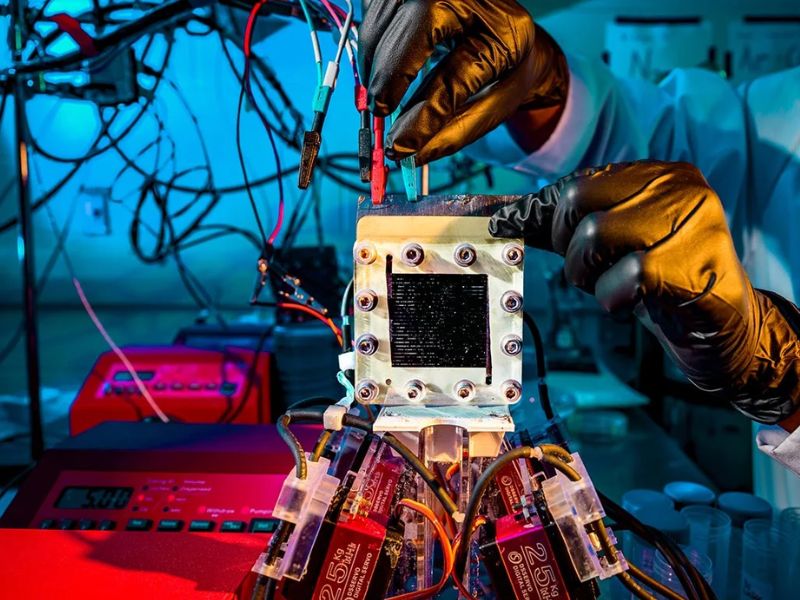

Smith’s research team built upon years of modeling and experimentation to develop electrodes with microchannels called interdigitated flow fields (IDFFs). Their latest study, published in Electrochimica Acta, takes this further by tapering the flow channels, which improved fluid flow—known as permeability—by two to three times compared to straight channels.

Addressing Dead Zones: Optimizing Flow with Tapered Channel Design

“Our initial work revealed dead zones within straight channels, causing pressure drops and uneven flow,” said graduate student Habib Rahman. “To address this, we tested 28 different straight channel designs to optimize flow, eventually implementing the tapered channel technique.”

Challenges and Future Applications

While the team encountered manufacturing challenges, particularly with the time-consuming process of milling tapered channels, Smith believes these obstacles can be overcome in large-scale production.

“Beyond desalination, our tapered channel design can be applied to any electrochemical device that uses flowing fluids, such as energy storage systems, fuel cells, and carbon capture devices,” Smith added. “Unlike previous impromptu channel-tapering designs, our method offers physics-based guidelines to achieve uniform flow and reduce pressure drops simultaneously.”

This study, supported by the Office of Naval Research, presents a promising advancement in both desalination technology and broader electrochemical applications. Smith, Rahman, and their co-authors have patents pending under U.S. patent applications 17/980,017, 17/980,023, and 63/743,995.

Read Original Article: Scitechdaily

Read More: Silver Foam and High-Power Lasers Create the World’s Brightest X-Ray