E-waste Recycling Yields Significant Profits

Depositphotos

Researchers have discovered a novel technique for reclaiming high-purity gold from discarded electronics, generating a return of US$50 for every dollar invested. Surprisingly, they found the crucial gold-filtering material in an unexpected source: cheese production.

Gold has been revered by societies for thousands of years. In modern times, its technical uses span various fields such as electronics, aerospace, medicine, biotechnology, and nanotechnology. However, being a non-renewable resource, gold’s value continues to rise steadily.

Revolutionizing Gold Extraction from E-Waste

In a recent investigation, scientists from ETH Zurich in Switzerland have outlined an eco-friendly and cost-efficient technique for specifically isolating gold from electronic waste, or e-waste.

“The aspect I find most fascinating is that we’re utilizing a byproduct from the food industry to extract gold from electronic waste,” remarked Raffaele Mezzenga, the lead author of the study. “It doesn’t get much more sustainable than that!”

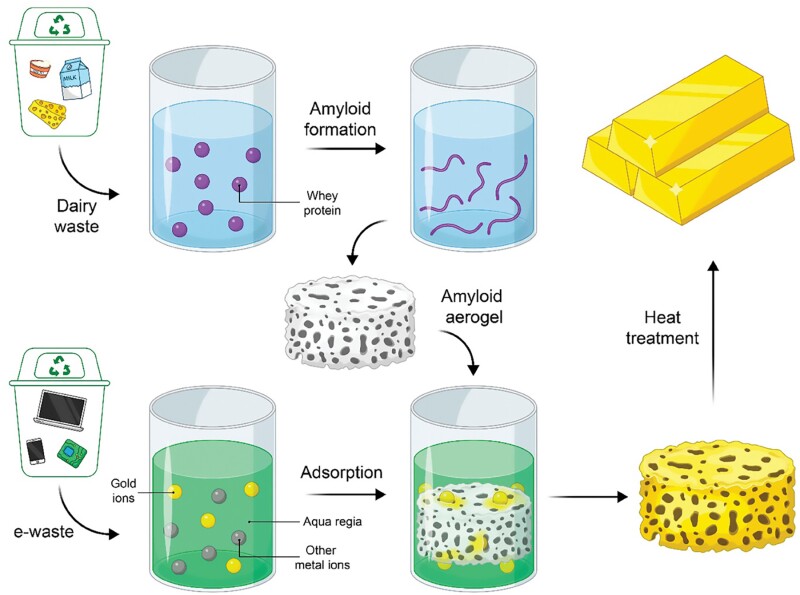

The byproduct from the food industry that Mezzenga mentions is whey, the liquid component of milk that separates from the curds during cheese production. The researchers transformed this waste from dairy production into a network of protein amyloid fibrils, which they employed as an adsorbent to target gold extraction from e-waste.

Under acidic conditions and elevated temperatures, the whey proteins underwent denaturation, causing their structure to break down into a more disordered state and aggregate into nanofibrils within a gel. This gel was subsequently dehydrated and molded into a sponge-like structure.

Peydayesh et al.

Scientists extracted metal components from 20 old computer motherboards and dissolved them in an acid solution to produce metal ions. When these ions interacted with the protein fibril sponge, gold adhered more effectively compared to other metals like copper and iron.

After absorbing the gold ions, the sponge was heated, transforming them into flakes that fused into a 500 mg gold nugget. Analysis revealed the nugget was primarily gold (90.8 wt%), with copper and nickel comprising 10.9 wt% and 0.018 wt%, respectively, indicating high purity around 21 or 22 karats.

Cost-Effective Gold Extraction

Their method proved economically feasible, with the total cost of extracting 1 g of gold from e-waste being 50 times lower than its value, covering material procurement and energy expenses.

Moreover, from an environmental perspective, the protein fibril sponge surpassed conventional activated carbon. While using activated carbon emitted roughly 116 g of carbon dioxide per 1 g of gold extracted, the protein sponge emitted about 87 g due to lower energy consumption during production.

Past gold extraction methods faced scalability issues. Despite potential ecological impact from its animal-based origin, researchers plan to investigate alternatives using plant-based proteins from sources like peas and potatoes.

The researchers intend to prepare the technology for commercialization. Although e-waste presents a promising initial source for gold extraction, they are exploring other potential sources, such as industrial waste from microchip production or processes involving gold plating.

Read the original article on: New Atlas

Read more: Direct Synthesis of Fluorinated Carbon Materials through Mechanochemical Reaction