RMIT

Styrofoam’s Potential for Generating Static Electricity

If you’ve ever had packing peanuts stick to your clothes while unboxing a delivery, you already know that Styrofoam generates a lot of static electricity. A new invention is now using this property to create a sustainable energy solution.

Polystyrene, better known as Styrofoam, is useful for protecting fragile items during transport or keeping coffee warm, but it’s an environmental problem as it can take up to 500 years to decompose in landfills. Despite this, global production of the material is around 26 million tons per year and continues to grow. It’s estimated that Americans alone discard 25 billion Styrofoam cups annually.

Innovative Solution: Multi-layered Adhesive Generates Electricity

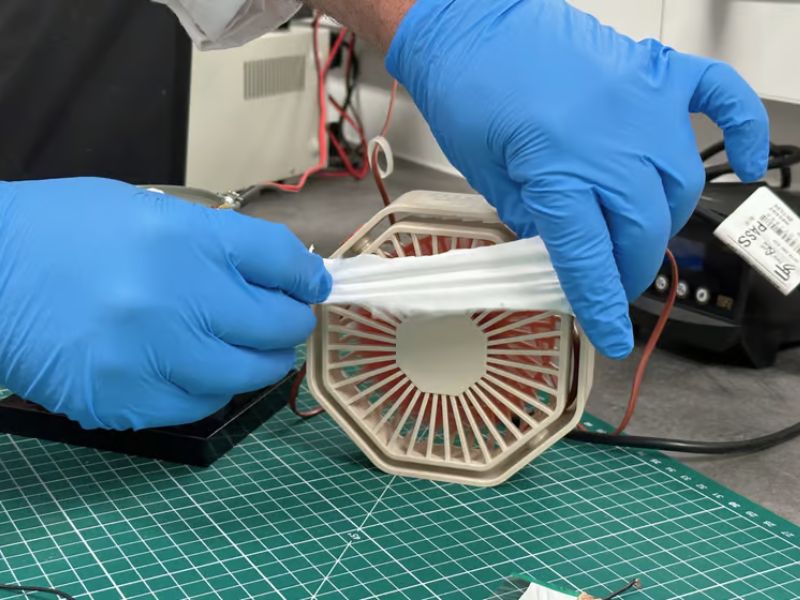

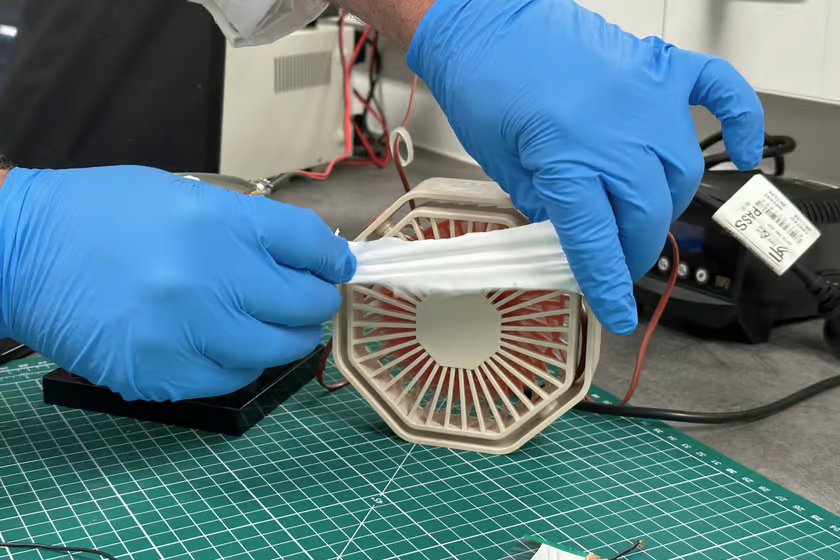

To make use of this waste, researchers at the Royal Melbourne Institute of Technology (RMIT), in partnership with Riga Technical University in Latvia, developed a thin adhesive made of multiple layers of Styrofoam. Each layer is about one-tenth the thickness of a human hair, and when exposed to wind, it generates static electricity that can be harvested. In tests, the adhesives generated around 230 volts, approximately double the voltage of a standard US outlet.

The inventors believe that these adhesives could be used to harness exhaust air from air conditioners, helping offset the carbon footprint and reduce the energy demand of these systems by around five percent. RMIT has filed a provisional patent for the invention and is looking for commercial partners.

Lead researcher Peter Sherrell explains that the best results come from compressing and separating the material, where larger, faster movements generate more energy, while smaller movements produce less. He suggests that in addition to air conditioners, high-traffic areas, such as underground walkways, could use these adhesives to supplement local energy without straining the grid.

Testing Plastics for Optimal Energy Production

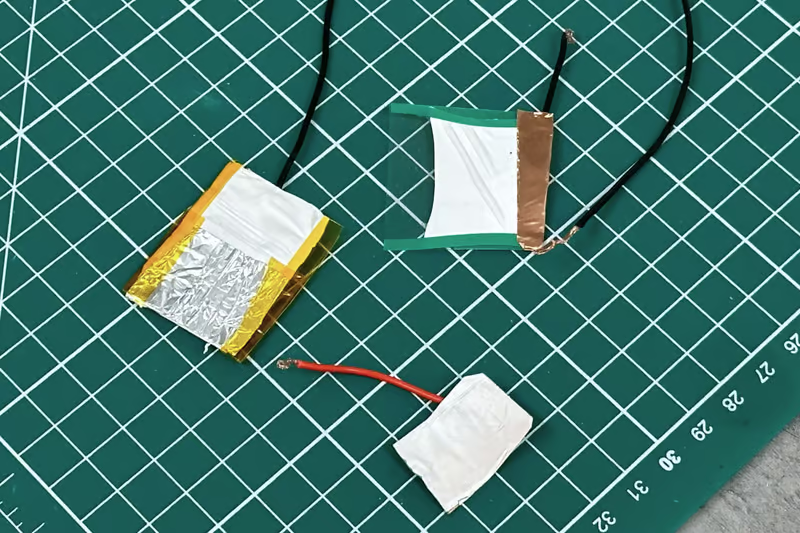

While developing the adhesive, the RMIT team tested various disposable plastics to optimize energy production.

We studied how different plastics generate energy and how this varies with structure—whether the surface is rough or smooth, thin or thick, said Sherrell. “All of our knowledge went into creating these small adhesives capable of producing a significant amount of energy.”

RMIT

The researchers also discovered how static electricity forms at the nanoscale level and developed a method to capture this process to produce a reliable current.

We learned how to make polystyrene layers rub together in a controlled way, aligning all charges in the same direction to produce electricity, Sherrell explained. “Over the past few years, we’ve gained a deeper understanding of this process.”

Sherrell explains that, because polystyrene consists of millions of small fibers that tangle when placed together, breaking these knots releases a small charge.

In addition to being efficient at generating electricity, these adhesives should also prove to be highly durable.

The fact that Styrofoam takes 500 years to decompose is also what makes these devices stable and capable of generating energy for a long time,” Sherrell concluded.

Read the original article on: New Atlas