A new study found that an algae-based plastic breaks down 97% in compost and water within seven months, even when crushed into tiny particles. Scientists hope this eco-friendly plastic will replace harmful petroleum-based ones. There’s been a lot of talk and research about microplastics, small bits of plastic that are hard to break down. Researchers are working on ways to clean up these microplastics to avoid health and environmental issues. However, a recent study from UC San Diego and Algenesis introduced a plant-based plastic that breaks down within seven months, even in microplastic form.

A New Material

“We’re just starting to figure out what microplastics mean,” said Michael Burkart, a professor at UC San Diego and one of the study’s authors. “We’re trying to find new materials to replace the ones we already use, and make sure these new materials break down naturally instead of staying in the environment. It’s not an easy task.”

Biodegradation is when tiny organisms break down big molecules into simpler ones. For this to happen, the molecules in the material need to be accessible to the enzymes that break them down, and the microbes need to be able to eat the molecules. Not all polymers are plastics, but all plastics are polymers.

“When we made these algae-based materials six years ago, we always wanted them to break down completely,” said Robert Pomeroy, another professor at UC San Diego and a study author. “We had data showing that our material was disappearing in compost, but this is the first time we’ve measured it at the tiny particle level.”

Turning Algae Into Fuel and the Creation of Biodegradable Plastic called TPU-FC1

Years ago, Pomeroy, Burkart, and Mayfield started a project to turn algae into fuel, but they switched gears to create a strong, biodegradable plastic called TPU-FC1. Since regular plastics come from oil, and oil comes from ancient algae, they decided to make plastics directly from algae oil. They used TPU-FC1 to make the world’s first shoes that can biodegrade. Pomeroy even wrote a book about this algae-based material.

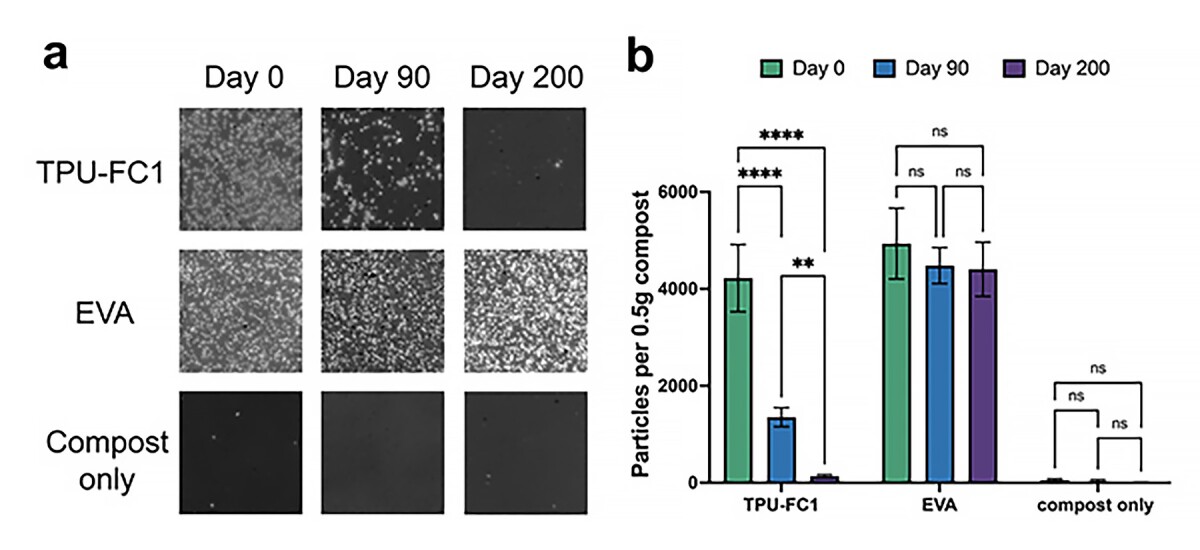

In their recent study, the researchers used a tool with sandpaper to make tiny pieces of different materials, including TPU-FC1. They made sure not to mix the materials. Then, they tested if microbes could break down these tiny plastics.

First, they put the tiny plastics in compost, which has microbes like those in a home compost. After 90 days, they found that TPU-FC1 decreased by 68%, while another material called EVA stayed almost the same. After 200 days, TPU-FC1 decreased by 97%, but EVA didn’t change.

Carbon Dioxide (CO2) Levels

A special set of samples with the same tiny plastics and compost was used to check carbon dioxide (CO2) levels. This was done using a machine called a respirometer. When microbes break down compost, they release CO2. Samples with only cellulose were used as a comparison to see how active the compost was. The cellulose samples reached 75% CO2 release within 45 days, showing that the compost was working well. As expected, the plastic made from EVA, which doesn’t break down easily, didn’t release any CO2 during the 200-day experiment. However, the TPU-FC1 plastic showed significant breakdown, releasing 76% of its carbon as CO2 in 200 days. This proves that TPU-FC1 can biodegrade, turning its carbon into CO2.

Since plastics don’t dissolve in water and float, they can be easily removed from the water’s surface. So, the researchers tested the tiny plastics by putting them in water. After 90 and 200 days, almost all of the EVA microplastics were still there, showing they hadn’t broken down. On the other hand, only 32% of TPU-FC1 was left after 90 days, and just 3% after 200 days, meaning 97% had broken down.

They also checked the chemicals in the algae-based plastic and found the original materials used to make it, showing that it had broken down. They even found bacteria that could eat TPU-FC1 and confirmed that they could break it down.

There is Hope

“This material is the first plastic that doesn’t break down into harmful microplastics,” said Stephen Mayfield, one of the study’s authors. “It’s not just good for the environment and reducing waste in landfills. It’s also safe for our health.”

Making this biodegradable plastic using regular manufacturing tools has been hard, but Algenesis is making progress. They’ve teamed up with Trelleborg to make coated fabrics and with RhinoShield to make phone cases.

“When we started, everyone said it couldn’t be done,” said Burkart. “But now we’re proving them wrong. There’s still a lot of work ahead, but we’re showing that it’s possible and giving people hope.”

Read the Original Article NewAtlas

Read more Microplastics Found in Human Organs, Even Brain, Study Says