Energy researchers are continuously exploring new battery technologies to advance the electronics industry. Their goal is to develop batteries that charge faster, last longer, and offer extended overall lifespans. Among the most promising options are all-solid-state batteries (ASSBs), which could meet these demands.

Unlike conventional lithium-ion (Li-ion) batteries that use liquid electrolytes, ASSBs rely on solid electrolytes. This design enhances safety since solid electrolytes are less likely to catch fire and allows for higher energy densities, meaning they can store more energy.

A key component of these batteries is the cathode active material (CAM), responsible for storing and releasing lithium ions. Nickel (Ni)-rich layered materials have shown great potential as CAMs, but they also present challenges. Studies have revealed that Ni-rich cathodes contribute to capacity fading—reducing the battery’s ability to hold a charge over time. This decline results from chemical reactions at the CAM-electrolyte interface, along with structural changes like expansion, contraction, and particle disintegration.

To better understand how Ni content affects battery degradation, researchers at Hanyang University in South Korea conducted a study published in Nature Energy. Their work led to the development of improved Ni-rich cathodes designed to enhance the performance and lifespan of ASSBs.

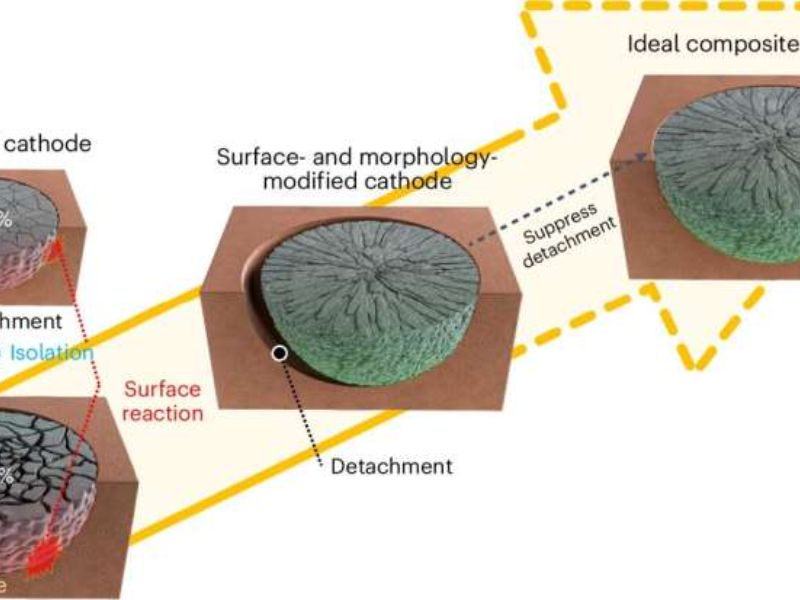

“ASSBs with Ni-rich layered CAMs and sulfide solid electrolytes hold great potential as next-generation batteries due to their high energy density and safety,” wrote Nam-Yung Park, Han-Uk Lee, and their team. “However, severe capacity fading occurs due to surface degradation at the CAM-electrolyte interface and drastic lattice volume changes, leading to inner-particle isolation and CAM detachment from the electrolyte.”

Analyzing Degradation: Investigating Ni-Rich Cathodes with Varying Compositions

To identify and quantify the factors contributing to degradation, the researchers synthesized four types of Ni-rich cathodes with varying Ni content (80–95%). These included pristine Li[NixCoyAl1−x−y]O2 cathode materials, boron-coated CAMs, Nb-doped CAMs, and CAMs that were both boron-coated and Nb-doped. They then analyzed how each variation affected the degradation process.

Their findings revealed that in cathodes with 80% Ni, surface degradation at the CAM-electrolyte interface was the primary cause of capacity fading. However, when Ni content exceeded 85%, inner-particle isolation and CAM detachment from the electrolyte played a more significant role.

Using these insights, the team engineered new Ni-rich CAMs with modified surfaces and structures. These materials featured columnar designs that reduced particle detachment and inner-particle isolation. When tested in a pouch-type full cell with a C/Ag anode-less electrode, the improved cathodes retained 80.2% of their initial capacity after 300 cycles.

This study provides valuable insights into the challenges of ASSBs and offers a pathway toward more durable, high-performance batteries. These advancements could accelerate the widespread adoption of ASSBs, bringing next-generation battery technology closer to reality.

Read Original Article: TechXplore

Read More: Engineers develop a more efficient burner to cut methane emissions.