Apptronik

View 3 Images

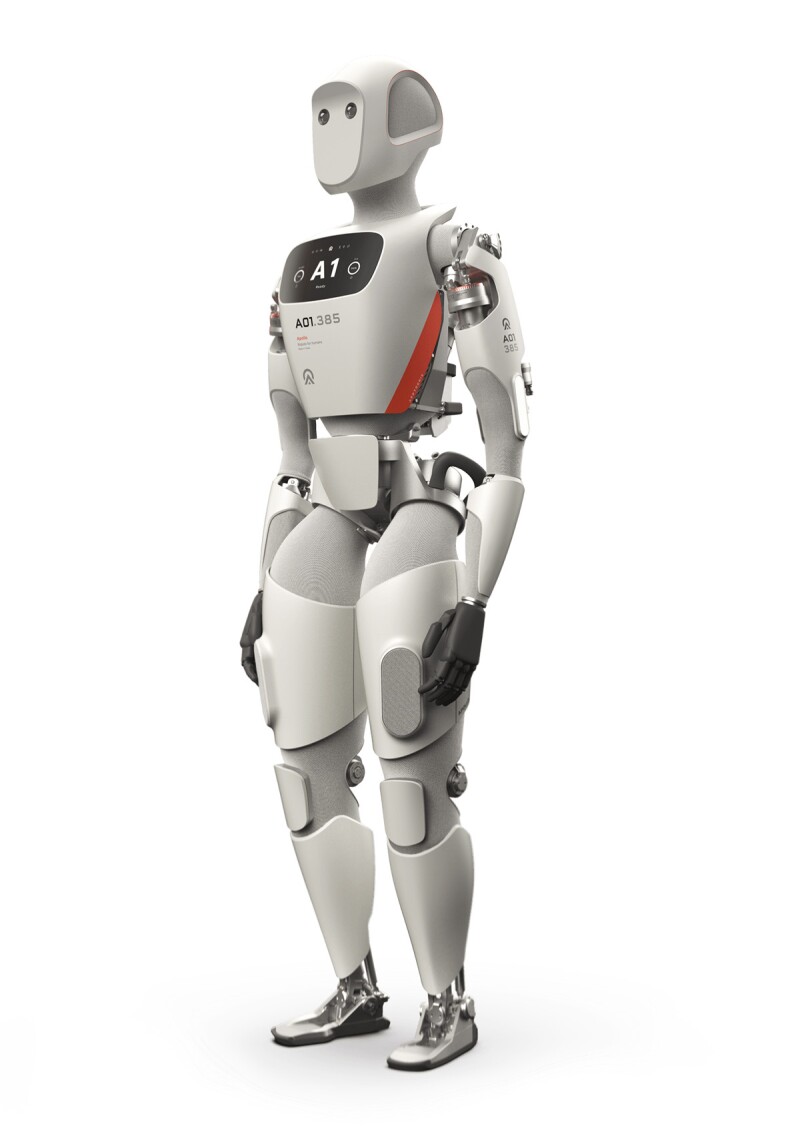

The self-replicating robot era may soon be upon us: Apptronik’s humanoid Apollo robot is preparing to help produce more copies of itself, thanks to a new partnership with global engineering firm Jabil. Jabil, which manufactures components for major brands like Apple, Dell, and HP, will integrate Apollo robots into its assembly lines, including those dedicated to building more Apollo robots.

Apollo’s Initial Tasks in Manufacturing and its Role in Future Production

Before it can start mass production, Apollo will need to prove its capabilities. Initially, it will handle a variety of simple, repetitive tasks, including inspection, sorting, kitting, lineside delivery, fixture placement, and sub-assembly. The ultimate goal is for Apollo to be deployed in active manufacturing environments to assist human workers.

Apptronik

Jabil also plans to scale up the production of Apollo robots, aiming to make them more affordable for Apptronik’s customers. First revealed in 2023, Apollo is expected to be commercially available next year.

Standing at 5 feet 8 inches (173 cm) and capable of carrying up to 55 pounds (25 kg), Apollo can operate for up to four hours on a single charge. Currently, it is able to perform basic tasks like loading cargo and moving items around warehouses, but the addition of product assembly tasks will mark a significant step forward for the bipedal robot.

Apptronik

Apptronik’s Vision for Apollo: Expanding Beyond Manufacturing

Apptronik envisions bigger things for Apollo. Earlier this year, the company sent Apollo robots to Mercedes-Benz to assist human workers in car production, although this project is still in the pilot phase. Additionally, Apptronik raised $350 million in a Series A funding round to scale up production and formed a partnership with Google DeepMind to integrate AI into Apollo.

Rafael Renno, Senior VP of Global Business Units at Jabil, emphasized the importance of this project for the future of manufacturing: “Not only will we gain insights into how general-purpose robots can impact our operations, but as we begin producing Apollo units, we can help shape the future of manufacturing.”

Price Predictions for Apollo and Industry Comparisons

Apptronik has not yet disclosed the price of Apollo when it hits the market, but we have some price references: Unitree prices its G1 robot at $16,000, and Tesla expects Optimus to cost between $20,000 and $30,000.

While Apptronik is still testing Apollo’s manufacturing capabilities, the company believes humanoid robots like Apollo will soon become widespread, entering new markets such as retail, elder care, and eventually home use.

Read the original article on: New Atlas

Read more: A New Learning Framework Enables Humanoid Robots to Quickly Recover and Stand Up After Falling