Interlune

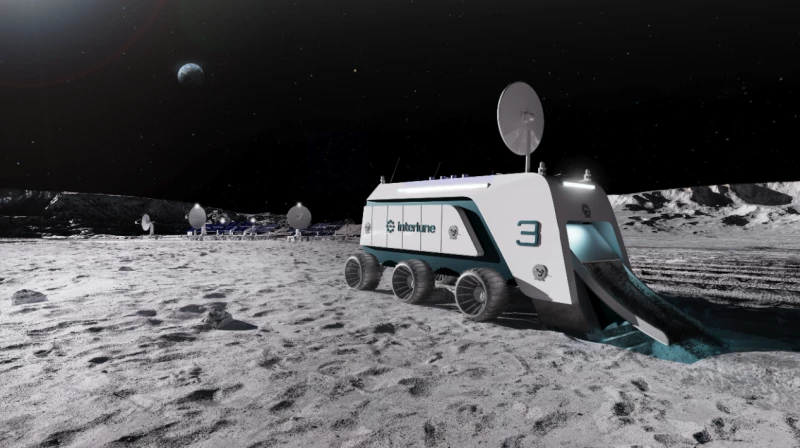

An American startup is turning its attention to the Moon in hopes of addressing a terrestrial resource shortage. While helium-3 is scarce on Earth, scientists believe the Moon’s surface layer, or regolith, contains a rich supply. Interlune, the company behind this initiative, has just unveiled a full-scale prototype excavator—an essential part of its planned lunar harvesting system.

Helium-3: A Critical and Dwindling Resource

Concerns about helium-3 availability—an isotope valued for its potential in clean energy production and critical medical uses—first gained attention in the U.S. around 2008. The government formally acknowledged the problem in 2009, initiating efforts to manage the limited supply.

According to a 2014 newsletter from the National Isotope Development Center, the U.S. has historically obtained helium-3 from the radioactive decay of tritium, a material tied to nuclear weapons production. But as the tritium stockpile has naturally decayed and demand has lessened, future supply has become increasingly uncertain.

Interlune

On Earth, helium-3 is incredibly limited. However, the Moon has long been exposed to solar wind, which is believed to have deposited significant amounts of this rare isotope onto its surface. Interlune plans to tap into this overlooked lunar resource and transport it back to Earth. The project has gained support from major organizations including NASA, the U.S. Department of Energy, and the National Science Foundation.

Four-Stage Harvesting Process Begins with Advanced Excavation

Interlune’s harvesting method includes four primary stages: excavation, sorting, extraction, and separation. For the excavation phase, the company collaborated with equipment manufacturer Vermeer to develop a smaller prototype last year. Now, the team has progressed to a full-scale version. Engineers designed this new electric excavator to operate with lower power consumption, reduced tractive force, and less dust generation than conventional trenching methods.

While specific technical details remain limited, Interlune reports that the machine is capable of continuously removing up to 100 metric tons of lunar soil per hour. The extracted regolith will be fed into the next stages—sorting, then processing for helium-3 separation.The team will return the leftover material to the Moon’s surface after extracting the resource.

Interlune

Other components of the system are also under active development and testing, including in conditions simulating lunar gravity and within Interlune’s cryogenic lab at its Seattle headquarters. The current roadmap includes a 2027 mission to verify helium-3 concentrations on the Moon, followed by the installation of a pilot plant by 2029. Interlune expects to begin commercial operations and deliver to customers in the early 2030s.

Interlune isn’t the only company preparing heavy machinery for lunar applications. Japanese firm Komatsu also showcased its own electric excavator at CES 2025, although their focus appears to lean more toward lunar construction rather than resource extraction.

Read the original article on: New Atlas

Read more: How Light Travels Across the Universe Without Losing Energy