Chalmers University of Technology | Henrik Sandsjö

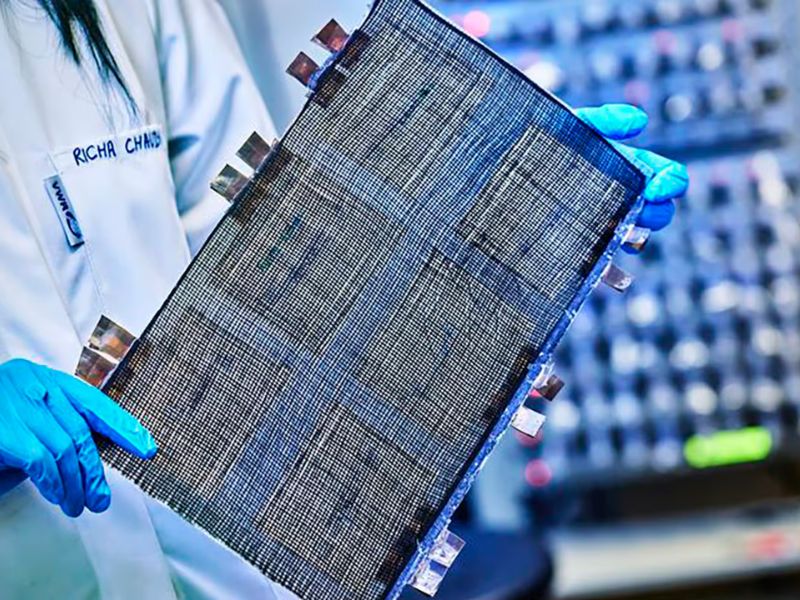

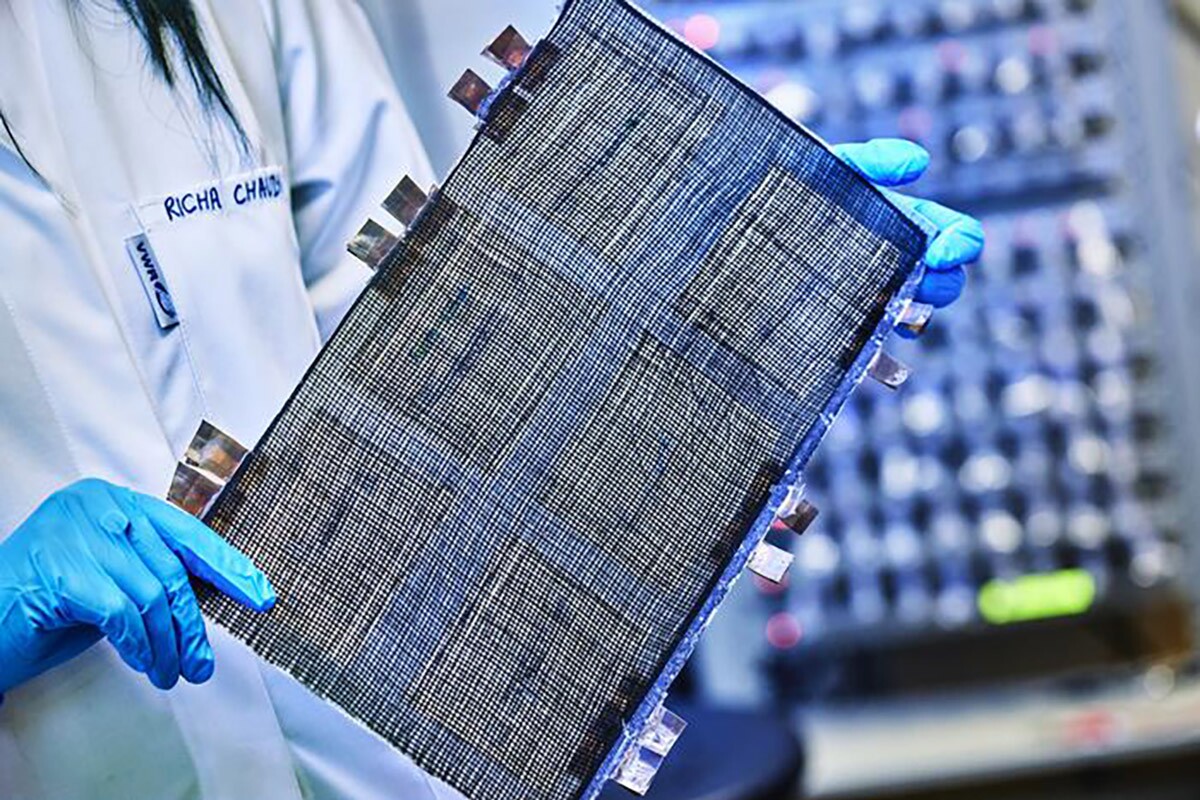

Researchers have developed and tested a “structural battery” that integrates energy storage into the chassis of a device or EV, significantly reducing weight. This innovation could enable smartphones as thin as credit cards, cut laptop weight in half, and increase EV range by 70%.

Electric vehicles typically depend on large lithium-ion batteries for extended range. Scientists at Chalmers University of Technology explored the possibility of creating a battery that also functions as a load-bearing component of the car, potentially reducing overall weight.

Swedish Team Develops Carbon Fiber Battery with Aluminum-Like Stiffness and Commercial Potential

In their research on “massless energy storage,” the Swedish team has created a battery using a carbon fiber composite. This battery offers comparable stiffness to aluminum and has the capacity to store a substantial amount of energy, making it commercially viable.

Chalmers University of Technology | Henrik Sandsjo

Carbon fiber is known for being extremely lightweight, strong, and rigid, making it a favored, though costly, choice for structural and exterior components in high-performance cars and a crucial material in aerospace where weight is critical.

Carbon Fiber as an Electrode

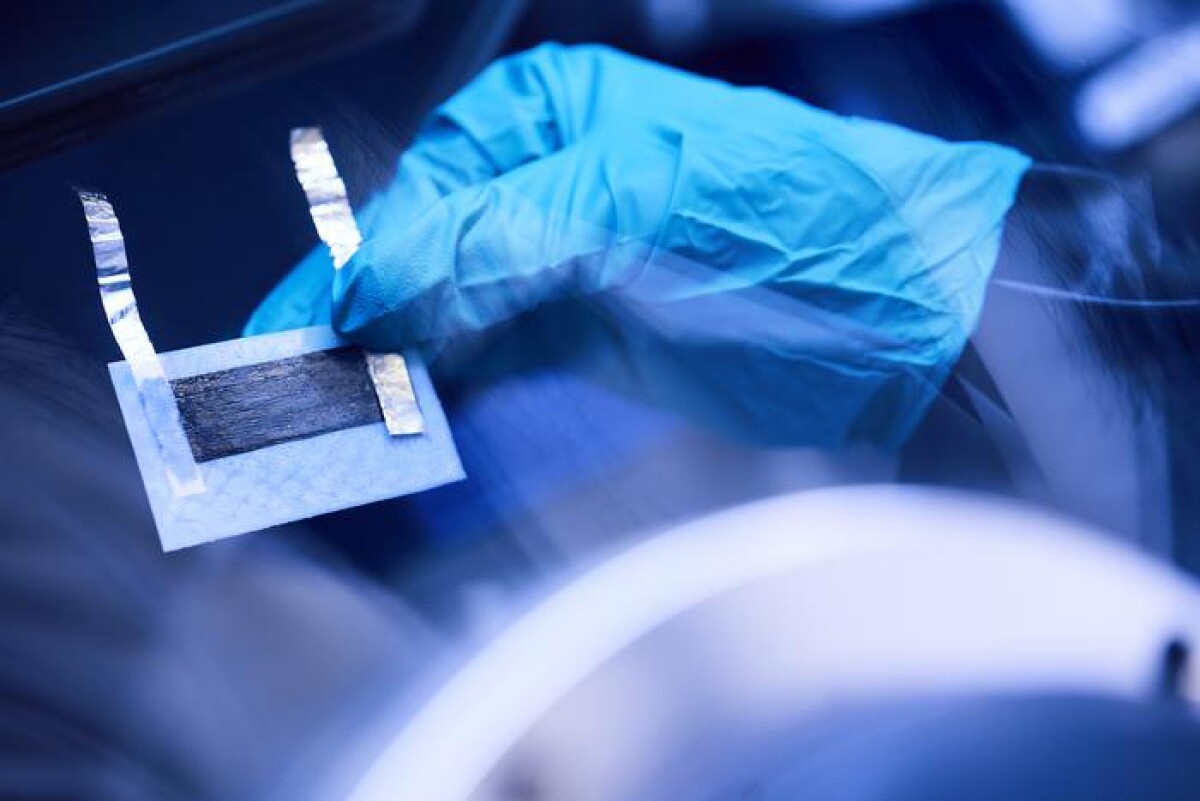

Additionally, carbon fiber can be an effective electrode material when specifically engineered for electrochemical applications. The Chalmers team, led by Professor Leif Asp, has been researching this for years and first showcased carbon fiber’s potential as an electrode material with a particular crystal arrangement in a 2018 study.

Chalmers University of Technology | Henrik Sandsjo

The new battery design boasts an energy density of 30 Wh/kg, which is relatively low compared to automotive standards. For context, the 53 kWh battery in a Hyundai Ioniq 6 has an energy density of 153 Wh/kg (see PDF).

Carbon Fiber Structural Battery

However, this comparison doesn’t account for the fact that the carbon fiber structural battery is intended to replace the entire vehicle frame, reducing the overall weight significantly and freeing up additional space. This means the total weight savings and space gained could offset the lower energy density.

Manufacturers have options with this new technology: they can either focus on making lighter products or use the extra space to add more cells and increase energy storage. This could lead to significant advancements. “Our calculations suggest that electric cars could potentially achieve up to 70 percent more range with competitive structural batteries,” says Asp.

The latest prototype is nearly three times stiffer than earlier models, with an elastic modulus of 70 gigapascals, up from 25. It now matches aluminum in rigidity and weight-bearing capacity while being much lighter.

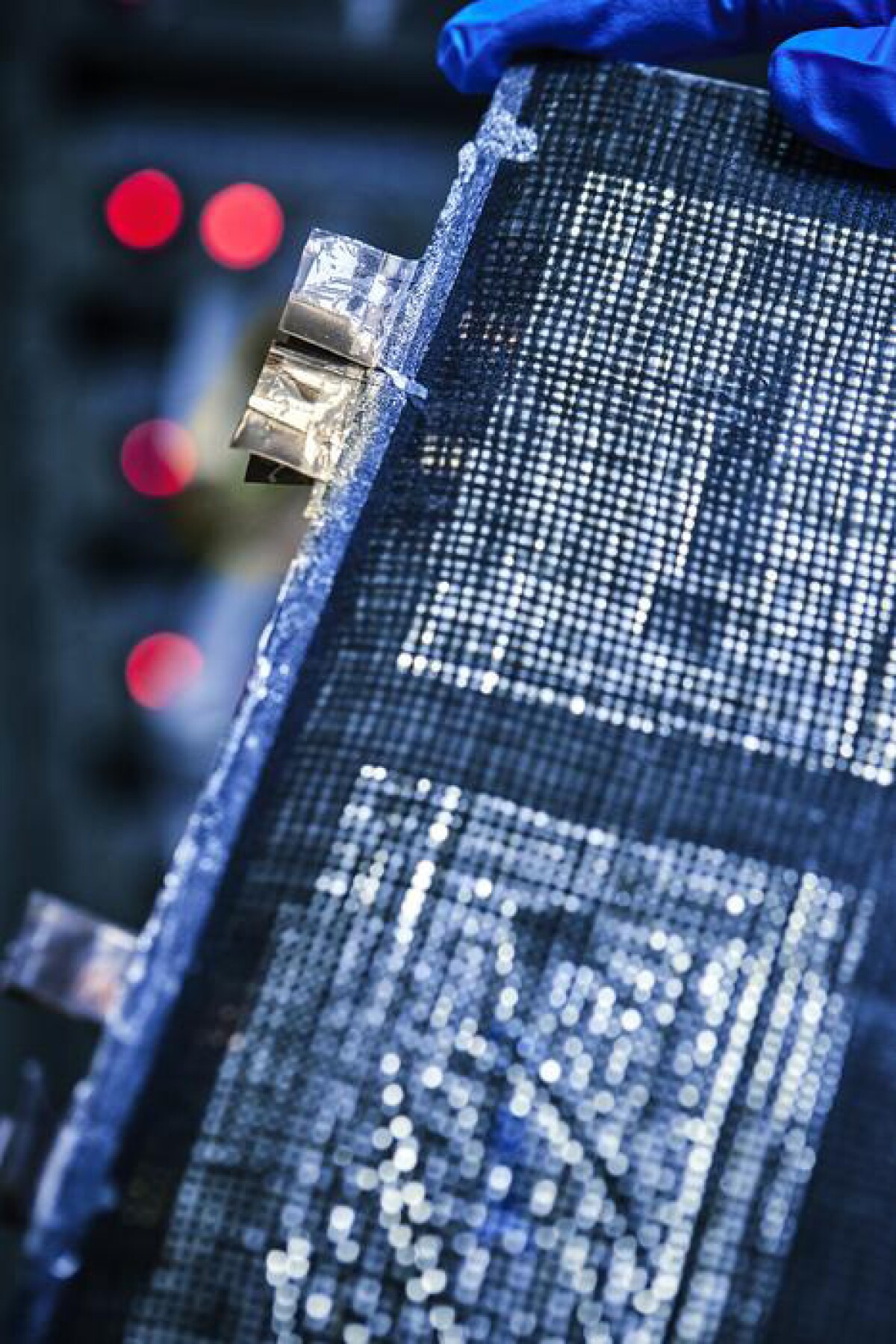

The battery design incorporates carbon fiber in both the anode and cathode, where it acts as both a reinforcement and a current collector. This eliminates the need for heavy materials like copper and conflict metals such as cobalt in the electrode design.

Chalmers University of Technology | Henrik Sandsjo

Semi-Solid Electrolyte Enhances Battery Safety, But Challenges in Ion Transport Remain

Additionally, this battery employs a semi-solid electrolyte instead of a liquid one to facilitate the movement of lithium ions between terminals. This makes the battery less flammable and safer to use. However, the team acknowledges that there are still challenges in achieving fast ion transport through the electrolyte for high-power applications, which requires further research.

Currently, this technology remains in the lab, and widespread adoption in EVs and devices is still a few years away. Nevertheless, efforts are underway to bring it to market.

In 2022, the university collaborated with Gothenburg-based VC firm Chalmers Ventures to create a new company called Sinonus. The company appointed a new CEO in June to advance the commercialization of massless energy storage, aiming to revolutionize the design of cars, gadgets, and even wind turbine blades.

“As Asp suggests, we could soon see credit card-thin smartphones or laptops that are half the weight of current models,” Asp notes. “Structural batteries might also power components in cars or airplanes. While meeting the transportation industry’s energy demands will require significant investment, this technology has the potential to make a substantial impact.”

Read the original article on: New Atlas

Read more: Why Selling Quantum Computing is Easier Than Selling a Quantum Computer