Zihui Zhou / UC Berkeley

Researchers at the University of California, Berkeley have developed a powdery material that adsorbs carbon dioxide with remarkable efficiency. Just 200 grams (about 0.5 pounds) can capture 44 pounds (20 kilograms) of CO2, equivalent to what a tree absorbs in a year.

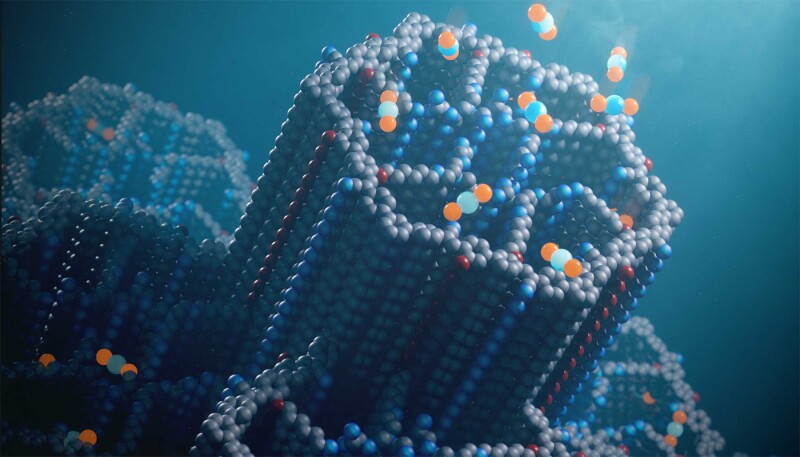

It’s known as COF-999, short for Covalent Organic Frameworks. This term describes a category of porous crystalline materials characterized by their large pores, high surface area, and low density. These features make them ideal for direct air capture (DAC), a method for removing existing CO2 from the atmosphere. With the current concerning levels of CO2 in the air, innovations like this are essential for addressing the issue.

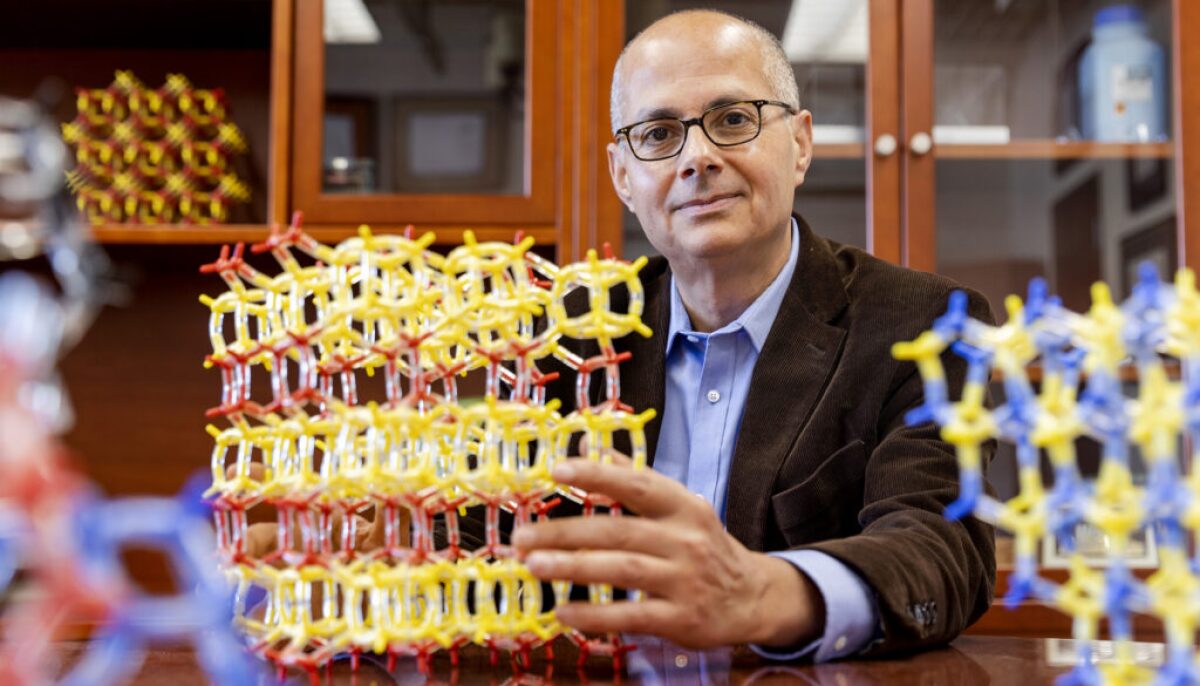

Developed by Pioneering Chemist Omar Yaghi and His UC Berkeley Team

The material was created by a team headed by Omar Yaghi, a chemistry professor at UC Berkeley and the pioneer of COFs. He has been working on similar materials since the 1990s.

COF-999 features pores adorned with amine compounds that can effectively capture CO2 molecules. Its porous design provides a significant surface area for carbon capture, and its covalent bonds are exceptionally strong. As air flows through the powder, the basic amine polymers in COF-999 bind with the acidic CO2, effectively trapping it.

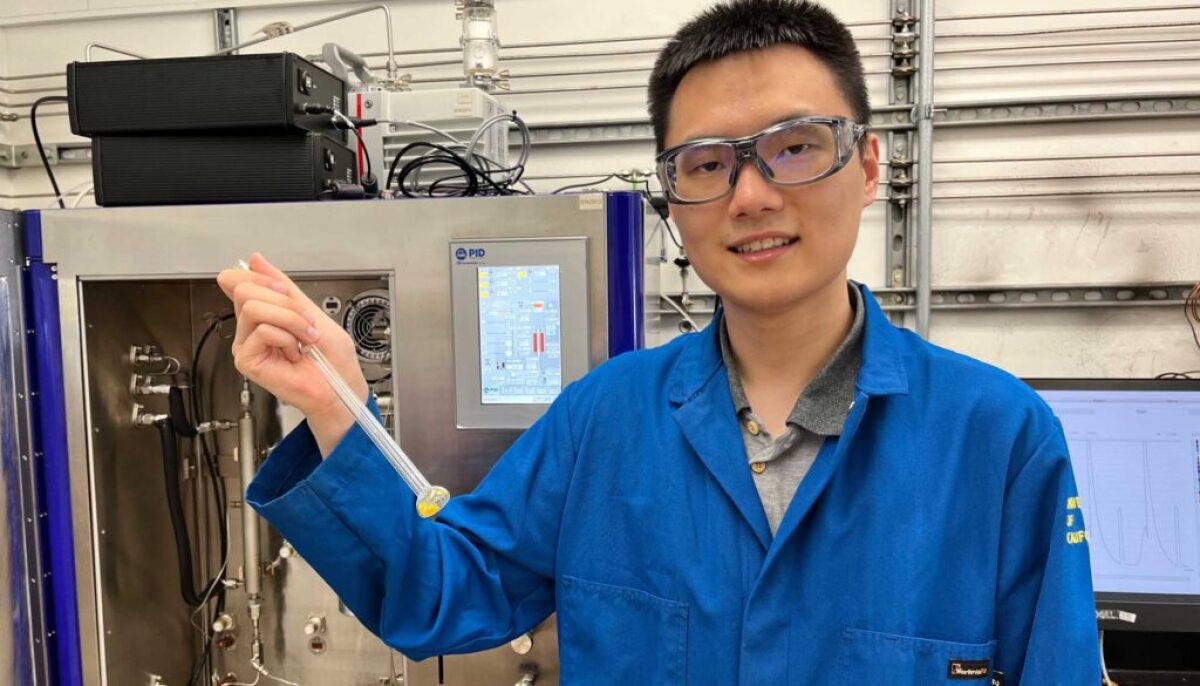

Chaoyang Zhao

A Room-Temperature, Durable Alternative to Traditional DAC Methods

Although previous DAC methods have relied on amine solutions in water, COF-999 offers several advantages for this purpose. For one, it operates effectively at room temperature, eliminating the need for heating. Additionally, it can be reused over 100 times without degradation or loss of efficiency, and it can selectively adsorb a significant amount of CO2.

Robert Sanders / UC Berkeley

Additionally, study leader Zihui Zhou informed the LA Times that COF-999 captures carbon dioxide “at least 10 times faster” than other direct air capture materials.

After the CO2 is captured by the powder, it can be heated to 140 ºF (60 ºC) to release it. The released CO2 can either be permanently stored in underground geological formations to prevent atmospheric pollution or utilized in manufacturing materials like concrete and plastic.

High Costs and Energy Demands Challenge Direct Air Capture (DAC) Expansion

Direct air capture (DAC) plants are already operating or being developed worldwide, but they come with high costs and require substantial energy. The World Economic Forum reports that current costs range from $600 to $1,000 to remove a ton of CO2 from the air; this price must drop below $200 for widespread adoption.

COF-999, however, still requires additional testing and refinement before large-scale use. According to Yaghi, this process may take around two years, during which the material could be optimized to capture more CO2 and endure more capture cycles before breaking down.

Brittany Hosea-Small for UC Berkeley

Yaghi is still uncertain about the production costs of COF-999, so its impact on reducing DAC expenses is yet unclear. However, he did mention that it doesn’t rely on costly materials, which is a promising factor.

Currently, the International Energy Agency reports that global CO2 capture rates stand at only 0.01 megatons per year—a small fraction of the 85 megatons needed annually by 2030. Looking further ahead, the Intergovernmental Panel on Climate Change projects that up to 10 billion tons of CO2 must be removed each year by 2050 to reach net-zero emissions.

There’s still significant progress needed, but promising breakthroughs like Yaghi’s innovative yellow powder offer hope. A paper detailing this study was recently published in Nature.

Read the original article on: New Atlas

Read more: Sunlight Converts CO2 and Methane into Valuable Chemicals