Solvang ASA

The oceans may be getting a little cleaner with the commercial launch of the Carbon Capture Solution (CCS) system, developed by technology company Wärtsilä. This modular system claims to capture up to 70% of the carbon dioxide emitted from cargo ship exhausts.

Growing Pressure to Cut Emissions

Driven by environmental concerns or the need to remain economically viable, shipping companies have shown increasing interest in reducing their carbon footprint. In 2022, cargo ships emitted around 858 million tonnes of CO₂, with larger vessels accounting for 79% of that figure. Currently, the maritime industry is estimated to contribute up to 3% of human-caused CO₂ emissions. To address this, the International Maritime Organization (IMO) has set a net-zero emissions goal for 2050. After that date, companies may face fines of up to US$380 per tonne of non-offset carbon, making technologies like CCS more relevant than ever.

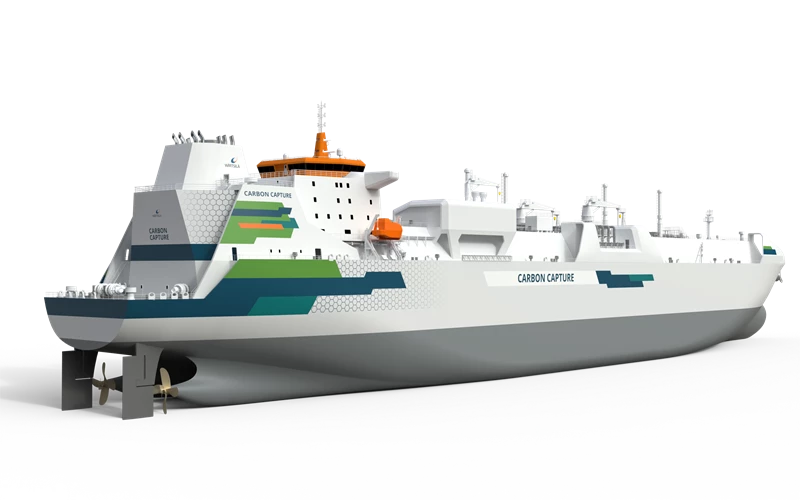

Since 2019, Wärtsilä has been working on developing its CCS system to capture CO₂ directly from the exhaust gases of ships powered by various fuels. While the technology itself is not new — its components have long been used in the gas, oil, and chemical industries — transforming it into a scalable, modular format suitable for both new and existing vessels marks a significant innovation. A major advantage of the design is its modularity, allowing easy integration with ships that already use exhaust scrubbing systems.

Wärtsilä

The CCS process involves five main stages. First, engine exhaust gases pass through filters that remove solid particles like soot and pollutants such as nitrogen and sulfur oxides.The system cools the exhaust and then directs it into an absorption chamber, where a liquid amine-based solvent captures the CO₂.Although the exact formula of the solvent remains proprietary, it likely includes compounds such as monoethanolamine (MEA), diethanolamine (DEA), or piperazine-based blends.

From Capture to Storage

The system then heats the CO₂-rich solvent in a stripping chamber, which releases pure CO₂ gas. It then compresses, dries, cools, and liquefies the gas before storing it in onboard tanks for later unloading at port.

According to Wärtsilä, the system can capture up to 70% of a ship’s CO₂ emissions.Experts estimate the cost to range from €50 to €70 (US$54 to $76) per tonne — significantly cheaper than the penalties expected in the future. If broadly adopted, this technology could help cut emissions by as much as 700 million tonnes annually.

Wärtsilä

Solvang ASA has installed the CCS system on the Clipper Eris, a 21,000 m³ ethylene carrier.

Since February 2025, when the ship departed from Singapore, it has been running with the complete CCS system. During tests, the system successfully captured 50 tonnes of CO₂ per day from engines using heavy fuel oil — a cost-effective but highly polluting fossil fuel.

Market Reception and Industry Collaboration

“This technology is a game-changer for the maritime industry, and we’re already seeing strong market interest,” said Håkan Agnevall, President and CEO of Wärtsilä. “With net-zero targets fast approaching, CCS supports the industry’s efforts to drastically reduce emissions and avoid stranded assets.”

Agnevall also emphasized the role of partnerships: “Achieving this breakthrough required close collaboration with like-minded partners such as Solvang ASA. We commend their forward-thinking approach and support in bringing CCS to their fleet.

Read the original article on: New Atlas

Read more: New Spongy Material Harvests Drinkable Water from Air in Emergency Situations