Old Wind Turbine Blades Recycled Into Stronger Plastics

Enrique / Pixabay

Recycling massive wind turbine blades challenges researchers because they use ultra-durable materials designed to withstand harsh conditions for decades.However, researchers at Washington State University have developed a smart way to take advantage of these properties and turn discarded blades into tough, long-lasting plastics—without using harsh chemicals.

Difficulty in Breaking Down Reinforced Material

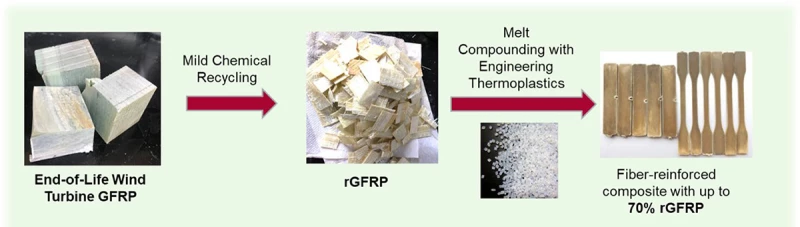

The main difficulty lies in breaking down the lightweight, hardened material used in many older blades from the 1990s: glass fiber-reinforced polymer (GFRP). Instead of fully breaking the material’s chemical bonds, the researchers found a more efficient approach.

“For this work, we didn’t need to fully break down all the bonds and push the reaction to completion,” explained Baoming Zhao, co-author of the study published in Resource, Conservation, and Recycling. “As long as we can break the cross-linked network into smaller pieces that are melt-processable, we can mix them with nylon and create a new composite.”

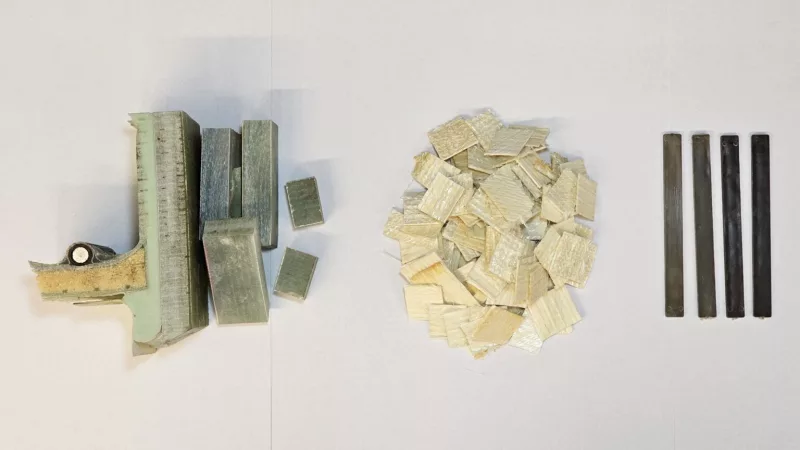

Washington State University

The process begins by cutting discarded turbine blades into 2-inch (5 cm) blocks, then shredding those into chips.The researchers soak these chips in a mild solution of zinc acetate (a low-toxicity organic salt) in superheated, pressurized water for two hours.

Promising Results in Material Performance

The researchers recover intact glass fibers and resin using this method, then blend them with melted thermoplastics—like those found in milk bottles—and nylon to create high-performance composite materials. The resulting recycled nylon plastic proved to be over three times stronger and eight times stiffer than standard versions.

Washington State University

The process also brings other advantages.The team filters and reuses the zinc acetate catalyst and also applies the technique to other widely used plastics, such as polypropylene, which appears in food containers, toys, and office supplies.

This innovation turns used turbine blades into valuable resources for plastic recycling facilities, all while preserving an environmentally friendly process. The researchers now work to lower the pressure requirements of their method to boost scalability and are also exploring recyclable materials for producing new turbine blades.

Markus Distelrath / Pixabay

If you’re into this kind of innovation, you might also enjoy other creative ideas for reusing wind turbine blades—like turning them into surfboards, road materials, or floating docks for saunas. Companies like Siemens Gamesa and GE are already producing recyclable blades, and bio-based resins could one day help decompose them more easily after use.

Read the original article on: New Atlas

Read more: Recycled Wind Turbine Blades Turned into Asphalt for New Roads