Xiaowei Song, Chanbasha Basheer, Jinheng Xu, Richard N. Zare

A new portable device, developed by researchers from Stanford University and King Fahd University of Petroleum and Minerals, promises to revolutionize ammonia production by eliminating the need for the energy-intensive Haber-Bosch process. This groundbreaking invention produces ammonia using only air, at room temperature and normal atmospheric pressure.

Significant Environmental Impact on the Horizon

If successfully commercialized on a global scale, this technology could significantly reduce the environmental impact of ammonia production. Ammonia is essential for applications like fertilizers and energy storage, but its current production methods consume about 2% of the world’s energy and generate roughly 1.2% of global carbon dioxide emissions. The widely used Haber-Bosch process relies on fossil fuels, operating at high temperatures and pressures, making it a major contributor to greenhouse gas emissions.

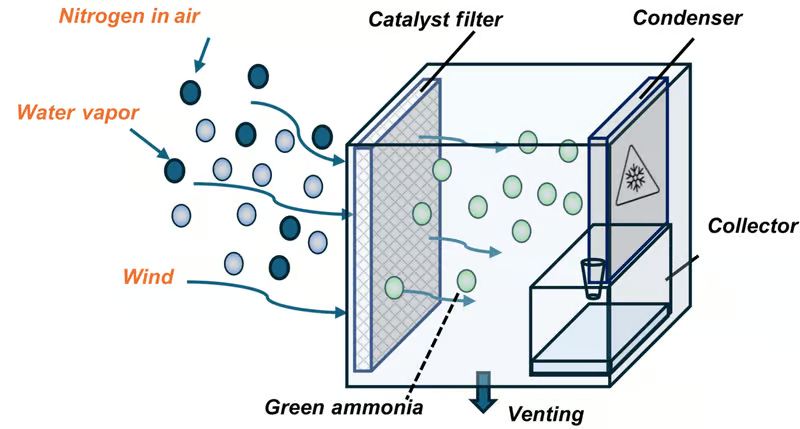

In a study published in Science Advances, the researchers detailed their device’s capability to produce ammonia outside laboratory conditions. The system utilizes a catalyst-coated mesh that extracts nitrogen from the air and hydrogen from atmospheric water vapor. As wind passes through the mesh, the device generates ammonia at a concentration suitable for hydroponic fertilizers—all without requiring high heat or pressure.

Xiaowei Song, Chanbasha Basheer, Jinheng Xu, Richard N. Zare

“This innovation represents a major step toward decentralized and sustainable agriculture,” explained Stanford professor Richard Zare, the study’s senior author. The device not only minimizes emissions from production but could also eliminate the need for ammonia storage and transportation, further reducing its carbon footprint. Researchers report that the process is cost-effective, providing a practical solution for local agricultural needs.

The Catalyst Mesh Behind the Breakthrough

Central to this advancement is the mesh developed by the research team, which combines magnetite with a Nafion polymer. When air flows through the mesh, nitrogen and water vapor react to form ammonia in usable quantities, sometimes in under an hour. The researchers believe this method could significantly cut fossil fuel reliance across various industries.

While the technology is still two to three years from commercial availability, the team is optimistic about scaling up production by enlarging the mesh and integrating it with a microporous stone filter. “Green ammonia is a transformative step in sustainability,” Zare emphasized. “If scaled economically, it has the potential to drastically reduce fossil fuel dependency in multiple sectors.”

With this and other advancements in sustainable ammonia production, the industry may soon see substantial reductions in its massive energy consumption and associated emissions.

Read the original article on: New Atlas

Read more: First U.S. Onshore Wave Energy Project Receives Green Light