Rotating Detonation Ramjet Engine For Hypersonic Flight in 2025

Venus Aerospace

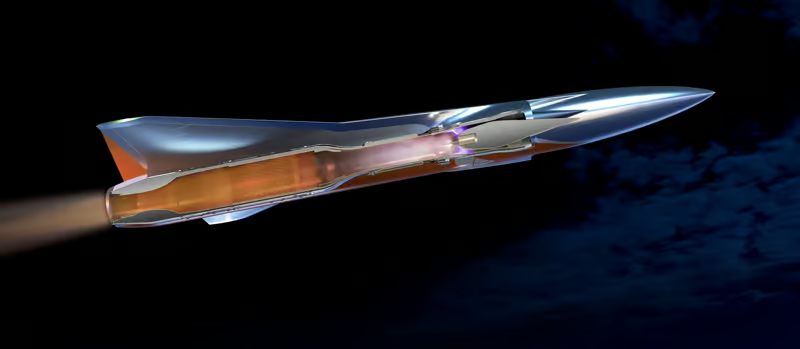

When does a hollow tube become more than just an empty tube? When it transforms into a ramjet that utilizes rotating detonation technology to achieve hypersonic flight. A prime example is Venus Aerospace’s latest innovation, the Venus Detonation Ramjet 2000 lb Thrust Engine (VDR2).

Overcoming the Challenge of Sustained Thrust

One of the main challenges in making hypersonic travel feasible is creating engines capable of providing sustained thrust.

Currently, most hypersonic systems rely on glide bodies that rockets boost to high speeds and altitudes, allowing them to glide back down while reaching speeds exceeding Mach 5. However, for airliners to fly from San Francisco to Tokyo in just one hour, a jet engine-like solution is necessary.

Recently unveiled at the Up.Summit in Bentonville, Arkansas, the VDR2 appears surprisingly straightforward in its cutaway view, essentially resembling a hollow tube with no moving components.This design reflects its nature as a ramjet, where the forward motion of the engine compresses incoming air instead of using spinning turbine blades, as traditional jet engines do.

The appeal of a ramjet for hypersonic flight lies in its ability to endure significantly higher temperatures than conventional engines, thanks to its simplicity and lack of moving parts. This capability is crucial since air entering the engine at hypersonic speeds can heat the interior to about 2,130 °C (3,860 °F), which would quickly damage turbine blades or similar parts.

Nevertheless, enhancements are possible. The VDR2 advances the technology by integrating a Rotating Detonation Rocket Engine (RDRE), which addresses the shortcomings of traditional rocket or jet engines through another innovative principle, again without moving parts. The RDRE within the VDR2 consists of two coaxial cylinders separated by a gap. A mixture of fuel and oxidizer is injected into this space and ignited. The subsequent detonation, if properly configured, creates a rapidly moving shock wave within the gap at supersonic speeds, generating additional heat and pressure.

Venus Aerospace

Achieving High Performance with Low Drag

The outcome is a low-drag engine, developed in collaboration with Velontra, building on previous work by Venus Aerospace. This engine offers the high thrust and efficiency required for aircraft to reach speeds up to Mach 6 and altitudes of 170,000 ft (52,000 m), boasting a 15% increase in efficiency compared to traditional engines if Venus Aerospace achieves its design objectives.

“This engine turns the hypersonic economy into a tangible reality,” stated Andrew Duggleby, CTO of Venus Aerospace. We are thrilled to partner with Velontra to revolutionize high-speed flight by leveraging their expertise in high-speed air combustion.

The team plans to conduct the VDR2’s first test flight using a test drone next year.

Read the original article: New Atas

Raed more: Next-Generation 3D Printed Catalysts to Propel Hypersonic Flight