The Most Efficient Hydrogen System in the World Scales up for Mass Production

Hysata guarantees the world’s most affordable hydrogen with a groundbreaking device that splits water into H2 and O2 at 95% efficiency, which is about 20% more efficient than the top conventional electrolyzers. The company has secured US$111 million to expand production.

Hydrogen production typically wastes 20-30% of renewable energy, contributing to high costs. Australian company Hysata’s capillary-fed electrolyzer offers 95% efficiency, using only 41.5 kWh of energy to create a kilogram of hydrogen. This reduces operational costs for hydrogen producers and CAPEX, making it the cheapest green hydrogen available.

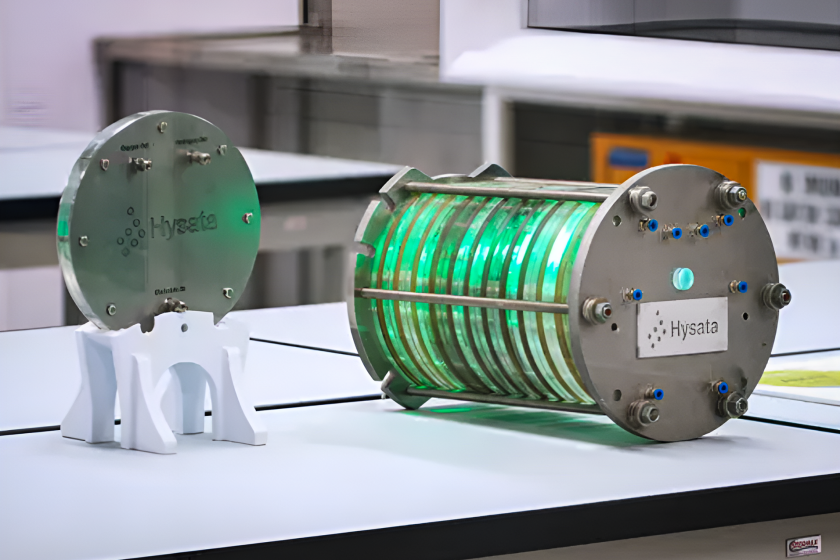

Hysata’s design, created by University of Wollongong scientists, “eliminates gas bubbles in the electrolyte, reducing resistance and energy waste.”

Revolutionary Design Enhances Electrolyzer Efficiency through Capillary Action

Hysata’s design places the electrolyte at the bottom, drawing it up through a porous separator between the electrodes. Each electrode contacts the electrolyte directly on the inner side, with a dry chamber on the outer side.

As the water ascends and splits into gases, there’s no bubbling through the liquid, significantly reducing resistance. Capillary action continuously draws more water up the central separator without needing a pump, vastly improving overall efficiency.

Breakthrough Efficiency

Indeed, Hysata claims to have measured the efficiency of this cell at up to 98% in laboratory conditions, as documented in peer-reviewed research published in the journal Nature Communications. Therefore, the 95% efficiency could be a realistic figure in real-world applications.

Hysata has announced a $111 million Series B investment round to expand production capacity and advance technology for gigawatt-scale manufacturing at its Wollongong, New South Wales facility.

On the surface, it appears to be positive news and a significant stride towards decarbonization. “Hydrogen holds promise as a clean fuel and energy storage solution in a zero-carbon economy, boasting higher energy density per weight than batteries and offering potential resolutions for challenging-to-decarbonize sectors such as aviation, shipping, heavy machinery, and long-haul trucking.”

However, Hystata, like other electrolyzer manufacturers, confronts challenging market conditions in the immediate future. BloombergNEF’s report reveals demand is the primary issue in the electrolyzer market, with only one profitable company in 2017 and others experiencing losses of up to US$1.4 billion.

According to Hydrogen Insight, “the main reason behind this trend is the slower-than-anticipated rollout of subsidies in the US and EU, prompting many demand-side developers to postpone or cancel their orders.”

By the end of 2023, global electrolyzer production capacity exceeded the expected delivery for 2024 by sevenfold. Moreover, numerous manufacturers have announced significant expansions, projecting a capacity increase of more than double by 2025. This projection does not even include new entrants to the market, further saturating an already crowded field.

Hysata’s unique cost/benefit equation may help ship units in difficult markets, but it may strain those financially. The USA’s 2022 Inflation Reduction Act may not align with green hydrogen incentives. Hysata’s technology ensures minimal renewable energy waste, but may not address energy lost in compression, cryogenic cooling, transport, or conversion.

Read the Original Article on: New Atlas

Read more: Yamaha Motor Unveils Hydrogen-Powered Outboard Motor Prototype