Recent advancements in materials science have unlocked new opportunities for bioelectronics manufacturing, especially for devices intended for use in or on the human body. These devices help monitor and support the function of organs, tissues, and cells, offering significant benefits for disease prevention and treatment.

One promising material for bioelectronics is PEDOT:PSS, a polymer valued for its high conductivity, flexibility, and compatibility with biological tissues. However, PEDOT:PSS dissolves in biological fluids, a challenge addressed by using chemical compounds and processes.

Researchers at Stanford, Cambridge, and Rice universities recently discovered a simpler and potentially safer method to stabilize this polymer using heat. Their thermal treatment, detailed in Advanced Materials, makes PEDOT:PSS films stable in water without requiring chemical additives.

Serendipitous Discovery Leads to Heat-Based Stabilization of PEDOT:PSS Films

This breakthrough began with a serendipitous observation by Siddharth Doshi during his prior research on shape-changing photonic devices. He noticed that baking PEDOT:PSS films at higher temperatures prevented them from dissolving in water. Intrigued, Doshi and his team explored how heating the films could stabilize them and improve their properties.

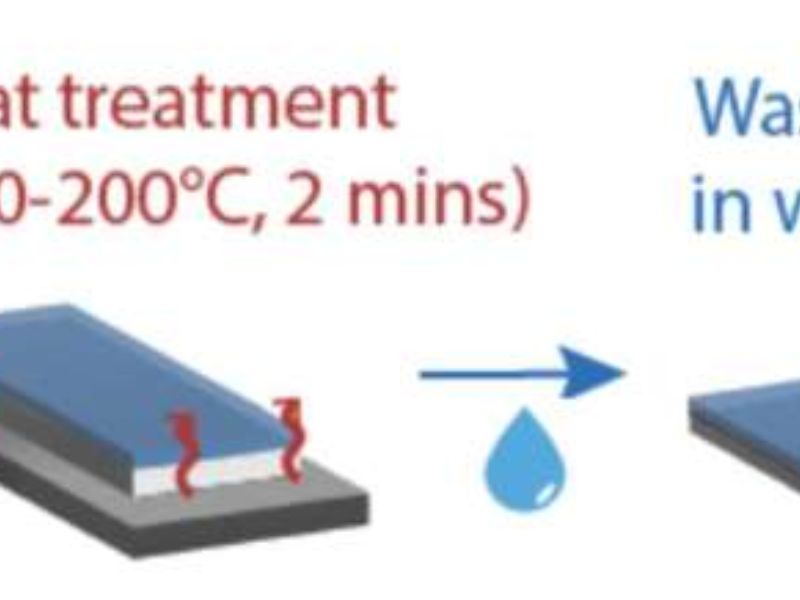

The researchers found that heating PEDOT:PSS films on a hot plate at temperatures between 150°C and 200°C for two minutes made them water-stable. This process works on various substrates, including stretchable plastics and fabrics, and avoids complications of chemical cross-linkers, which can compromise conductivity and reliability.

Their heat-based approach also enables easy patterning of PEDOT:PSS films by applying heat to specific sites, eliminating the need for complex lithography techniques. Additionally, they demonstrated 3D printing of PEDOT:PSS using a femtosecond laser to create stable, patterned structures with water as the only processing solvent.

Heat Treatment Enhances Performance and Stability of Bioelectronic Devices

The heat treatment led to significant improvements in the performance and stability of bioelectronic devices. For example, devices such as transistors and spinal cord stimulators were easier to fabricate, more reliable, and robust in in vivo experiments lasting over 20 days.

This heat treatment works by inducing phase separation of the polymer, creating a water-insoluble, PEDOT-rich phase that enhances both conductivity and capacitance—key factors for bioelectronic devices.

Furthermore, this method can easily integrate into existing manufacturing processes, simplifying the development of PEDOT:PSS-based devices, including bioelectronics and wearable electronics.

The researchers are also excited about the potential for 3D printing functional polymers at the microscale, which could revolutionize the interface between bioelectronics and biological systems.

In future studies, Doshi and his team plan to explore the fundamental mechanisms behind the stabilization process using advanced imaging and material characterization techniques, such as in-situ transmission electron microscopy or X-ray diffraction.

Read Original Article: TechXplore

Read More: MIT Challenges Conventional Understanding of Evaporation